Image Credit – Hema

In today’s fast-paced food industry, maintaining safety, hygiene, and quality is more important than ever. One of the most trusted and globally recognized systems that ensure food safety is the HACCP, short for Hazard Analysis and Critical Control Point. Whether you are a food manufacturer, restaurant owner, or home-based food entrepreneur, understanding and implementing HACCP is essential to protect consumers and build trust in your brand. In this blog, we’ll break down what HACCP is, why it’s important, and how it works to keep food safe from production to consumption.

Understanding The HACCP – The Key to Food Safety and Quality Assurance

What is HACCP?

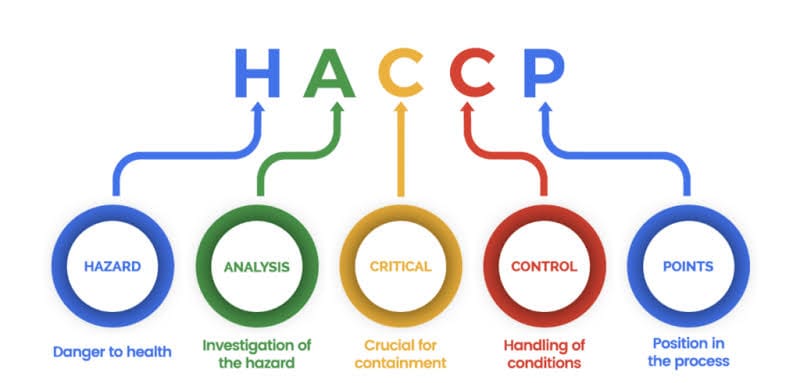

The HACCP stands for Hazard Analysis and Critical Control Point, a systematic approach to identifying, evaluating, and controlling potential hazards in food production and processing. These hazards can be biological (like bacteria or viruses), chemical (like cleaning agents or toxins), or physical (like glass or metal fragments).

The HACCP system was originally developed by NASA in collaboration with food scientists to ensure that the food astronauts consumed in space was completely safe. Today, it is a globally accepted standard for food safety management used by businesses across the food supply chain — from farms to factories, and from kitchens to consumers.

The Importance of HACCP in the Food Industry

Implementing HACCP is not just a legal requirement in many countries but also a key part of maintaining public health and consumer confidence. Here are some reasons why HACCP is crucial:

- Prevention over Reaction:

HACCP focuses on preventing hazards before they occur, rather than inspecting and reacting after problems arise. - Ensures Food Safety:

By identifying potential hazards and controlling them, HACCP helps prevent foodborne illnesses and contamination. - Compliance with Regulations:

Many governments and certification bodies require HACCP compliance for food production and export. - Builds Consumer Trust:

Businesses that follow HACCP demonstrate their commitment to delivering safe, high-quality products. - Reduces Wastage and Costs:

Preventing contamination and spoilage saves time, resources, and money for food businesses.

The Seven Principles of HACCP

The HACCP system operates on seven core principles designed to identify and control hazards at every stage of food production.

- Conduct a Hazard Analysis:

Identify potential hazards that could make food unsafe, such as microbial contamination or foreign objects. - Determine Critical Control Points (CCPs):

These are specific steps in the process where control can prevent or eliminate hazards — for example, cooking or cooling stages. - Establish Critical Limits:

Define the acceptable range for each CCP, such as minimum cooking temperature or maximum storage time. - Establish Monitoring Procedures:

Set up a system to regularly check that CCPs stay within their limits (e.g., using temperature logs). - Establish Corrective Actions:

Decide what steps to take if a critical limit is not met, such as discarding affected food or reprocessing. - Establish Verification Procedures:

Confirm that the HACCP system is working effectively through audits and testing. - Establish Record-Keeping and Documentation:

Keep detailed records of all HACCP procedures, monitoring results, and corrective actions for accountability and compliance.

How to Implement HACCP in Your Business

To successfully apply HACCP, a food business should start by forming a dedicated HACCP team trained in food safety. This team should analyze the production process, identify hazards, and apply the seven principles systematically. Many organizations also seek certification through recognized food safety authorities to show compliance with international standards.

Training employees at all levels about hygiene, handling, and monitoring procedures is also vital. Consistent audits, updates, and reviews ensure that your HACCP plan remains effective even as processes change.

The HACCP is more than just a safety standard — it’s a proactive approach to protecting public health, maintaining quality, and ensuring consumer trust. By implementing HACCP, food businesses can detect risks early, prevent contamination, and maintain compliance with global safety laws. Whether you run a small café or a large-scale manufacturing plant, adopting HACCP practices helps build a reputation for reliability, safety, and quality.

Let us know in the comments if your business uses HACCP and how it has helped improve your food safety standards.

Frequently Asked Questions

What is HACCP and why is it important in the food industry?

HACCP (Hazard Analysis and Critical Control Point) is a food safety management system designed to identify and control potential hazards during food production. It’s important because it helps prevent contamination, ensures food safety, and builds consumer trust by maintaining high hygiene standards.

How can I implement HACCP in my restaurant or food business?

To implement HACCP, start by analyzing potential hazards, identifying critical control points, setting limits for safety, and creating monitoring procedures. Training your staff, maintaining records, and performing regular audits are also key steps in an effective HACCP plan.

What are the seven principles of HACCP and how do they work?

The seven principles of HACCP include hazard analysis, identifying critical control points, setting critical limits, monitoring, taking corrective actions, verifying procedures, and record-keeping. Together, they help food businesses systematically prevent, detect, and manage food safety risks.